LINER-LESS LABEL

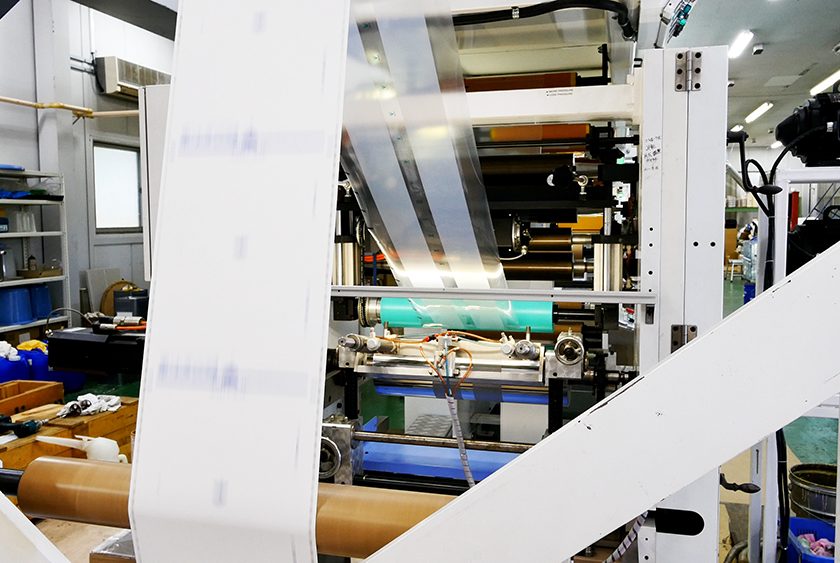

The linerless label led an answer to the problems such as the reduction of label, exploitation of resources-saving, reduction of the garbage, the increase of the number of labels in 1 roll.Solution to produce labels without the liner is not at all special processing, and there is it from past, and the tape with the print which is used a lot now is right linerless. We can cut down 35% of constitution cost of the present normal label just to zero detachment liner. It was the constitution that could produce linerless labels from COHESIO, an ETI establishment of a business original machine anytime.In recent years many manufactures Linares label-only machines, but Linares label is rectangular-only.ETI offers two systems as a universal type Linares label production solution.

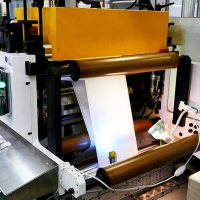

Hot-melt patterns coating plate cylinder replacement

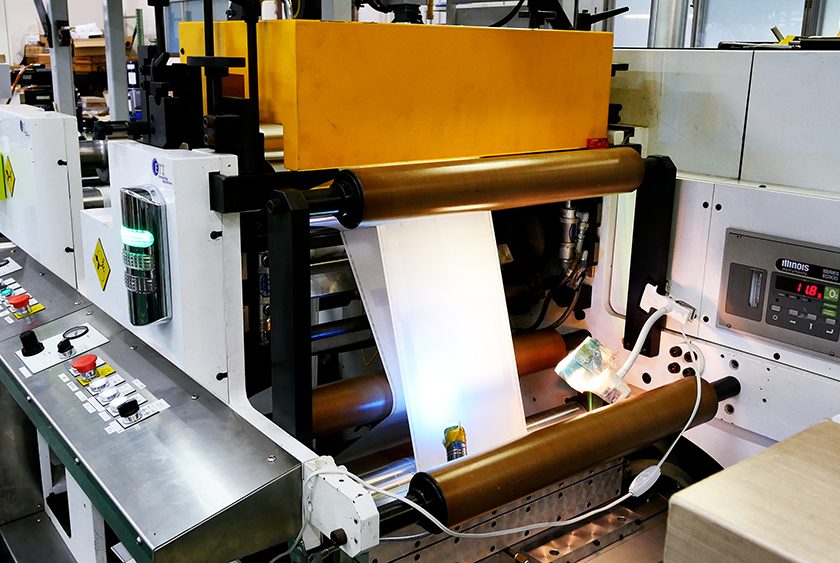

This system is made into the standard in ETI. Although the hot melt adhesion has already satisfied all the demands from the industry in respect of the physical properties as an adhesive, when the turn to hot melt adhesion is not allowed, please employ the emulsion coating equipment of our company.

1. Use adhesive : hot melt adhesive

2. adhesive type : [ Rubber system, ] Product slot mask coating made from EVA system and acrylics system

3. system:ETI

4. feature: Develop at ETI company so that the adhesion layer formation where even the bright film base material was stabilized for high quality from paper may be possible.

5. coating tunic: Less than ±5% 6. speed: Top speed 150 m

Direct thermal layer coating

1. It is possible to use direct thermal label with any base materials. By carrying out

2. By carrying out partial coating, regulation of the area which can be colored is possible.

Regulation of the area which can be colored is possible. Creation of the style of the new label which unified the document and the label combining

3. pattern adhesion coating is possible. Only overcoat is given to the ETI COHESIO machine of

4. Extension to the existing ETI COHESIO machine is possible

5. ready-made [ which can be extended ] general-purpose thermal paper,

Upgrade on high tolerance thermal paper is possible.

Emulsion adhesive CORTER

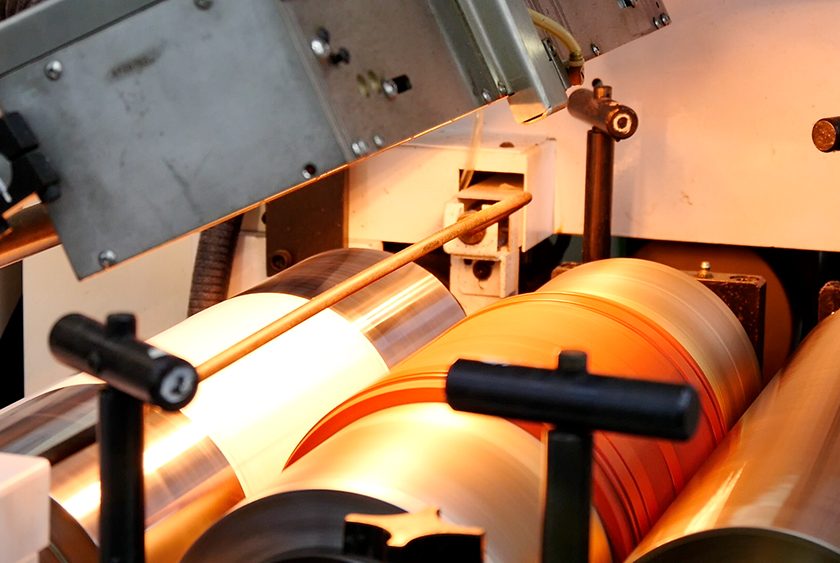

1. gravure printing system for emulsion adhesion

2. Use adhesive Emulsion adhesive Printing is also usually viscosity corresponding to possible

3. 500-5,000c.p.s.

4. pattern adhesion printing The photogravure version trunk exchange system

5. cylinder exchange is possible. Circumference 15.75-29.5 inches

6. system right and reverse change are possible. Photogravure coating

Mini-liner system

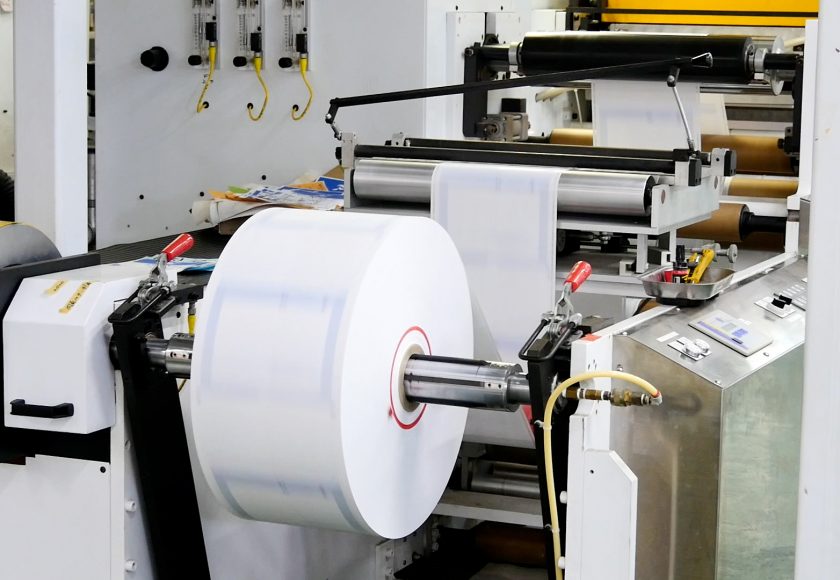

12 microns of PET film is peeled, the system to produce a label as a liner. It’s to adopt a PET liner, and increases in the number of labels in 1 roll in about an average of 1.6 while also maintaining the sticking precision of Ra of Labe. Moreover 12 microns of PET film is less than 1/2 of the price of GURASHIN, and cost cutting is possible while maintaining the Labe Ra aptitude. It’s also the very effective new label form from a face of the environment and a measure of resources. Or you keep a used liner on the user side, and a printing company is to collect that and process recycling, and because a silicon paper liner is repealed as trash of resources, you can turn. A ETI DOHESIO machine is the machine which feeds a web stencil of non-processing, pastes silicon nurikou and adhesion nurikou together and does processing without a label for labels printed beforehand. It’s to print a label beforehand in the film back, and you can laminate it exaggeratedly and also reduce varnish processing by making the film plane which isn’t being printed a label table. When adding the function of "mini liner" to this system, it becomes possible to achieve more substantial cost cutting.

Hot melt slot mask system coating

In the physical-properties side as an adhesive, it is hot melt adhesion. Place where the turn to hot melt adhesion is not allowed although I have already satisfied all the demands from the industry Please employ the emulsion coating equipment of our company.

1. Use adhesive : Hot melt adhesive

2. adhesive type : Rubber system, An EVA system, acrylics system

3. system : Product slot mask coating made from ETI The 4. feature : It develops at ETI company so that the adhesion layer formation where even the bright film base material was stabilized for high quality from paper may be possible.

5. coating tunic : Less than ±5%

6. speed: Top speed 150 m

SPECIFICATION

COHESIO-Domestic rare strongest adhesive label presses

Hot melt Pattern coating Exchange type forThe coating version trunk. This system is made into the standard in ETI. In respect of the physical properties as an adhesive, hot melt adhesion already satisfies all the demands from the industry. Please adopt the emulsion coating equipment of our company when the turn to hot melt adhesion is not allowed.

1.Use adhesive:Hot-melt pressure-sensitive adhesive

2.Adhesive type:Rubber system, EVA system, acrylic system

3.System:Slot mask coating made by ETI

4.Feature:It develops at ETI companyfor the adhesion layer formation where even the bright film base material was stabilized for high quality from paper is possible.

5.Coating film:Less than ±5%

6.Speed:150 meters of max speed

Emulsion tacky producer coater

1.Emulsion:The gravure printing system for adhesion

2.Adhesive type:Emulsion adhesive Printing is also usually possible.

3.Correspondence viscosity :500~5,000cps

4.Pattern adhesion print:Adhesion printing The photogravure version trunk exchange system

5.A cylinder is exchangeable:15.75-29.5 inches of circumferences

6.System:Forward and reverse switchable gravure coating

PRODUCTS

Various label printing(Linerless)・Gravure printing